Blog: How SPC Flooring Meets Global Safety Standards

- Oct 3, 2024

- 2169

Introduction

With the increasing popularity of SPC flooring due to its durability and water resistance, easy installations, and its international safety standards becoming relevant also to customers as more homeowners and businesses use these products, the product will ensure that its materials used in homes or commercial spaces are safe, reliable, and environment-friendly. We shall see below how SPC flooring meets and goes beyond safety standards around the world and how this flooring is ideal for residential and commercial application.

Global Safety Standards Overview

Global safety standards would refer to the existing set of norms and regulations put in place to ensure that products intended for use or distribution, like flooring, ensure a safety, healthy, and environmental-friendly condition in which they will be used. The most significant bodies behind developing and standardizing such global standards include the International Organization for Standardization (ISO), the European Committee for Standardization (CEN), and the American Society for Testing and Materials (ASTM). These standards would cover the spectrum of aspects, from fire resistance and slip resistance to level of chemical emissions and even the environment. Such standards are basic requirements so that flooring materials from all the manufacturers across different countries meet the required safety standards.

Floormonk SPC flooring meets several global standards, ensuring high quality and performance. Here are the key standards that Floormonk SPC flooring adheres to:

-

Size: Complies with EN 427 (Pass) and ASTM F536 (Pass).

-

Overall Thickness: Meets EN 428 (Pass) and ASTM F36 (Pass).

-

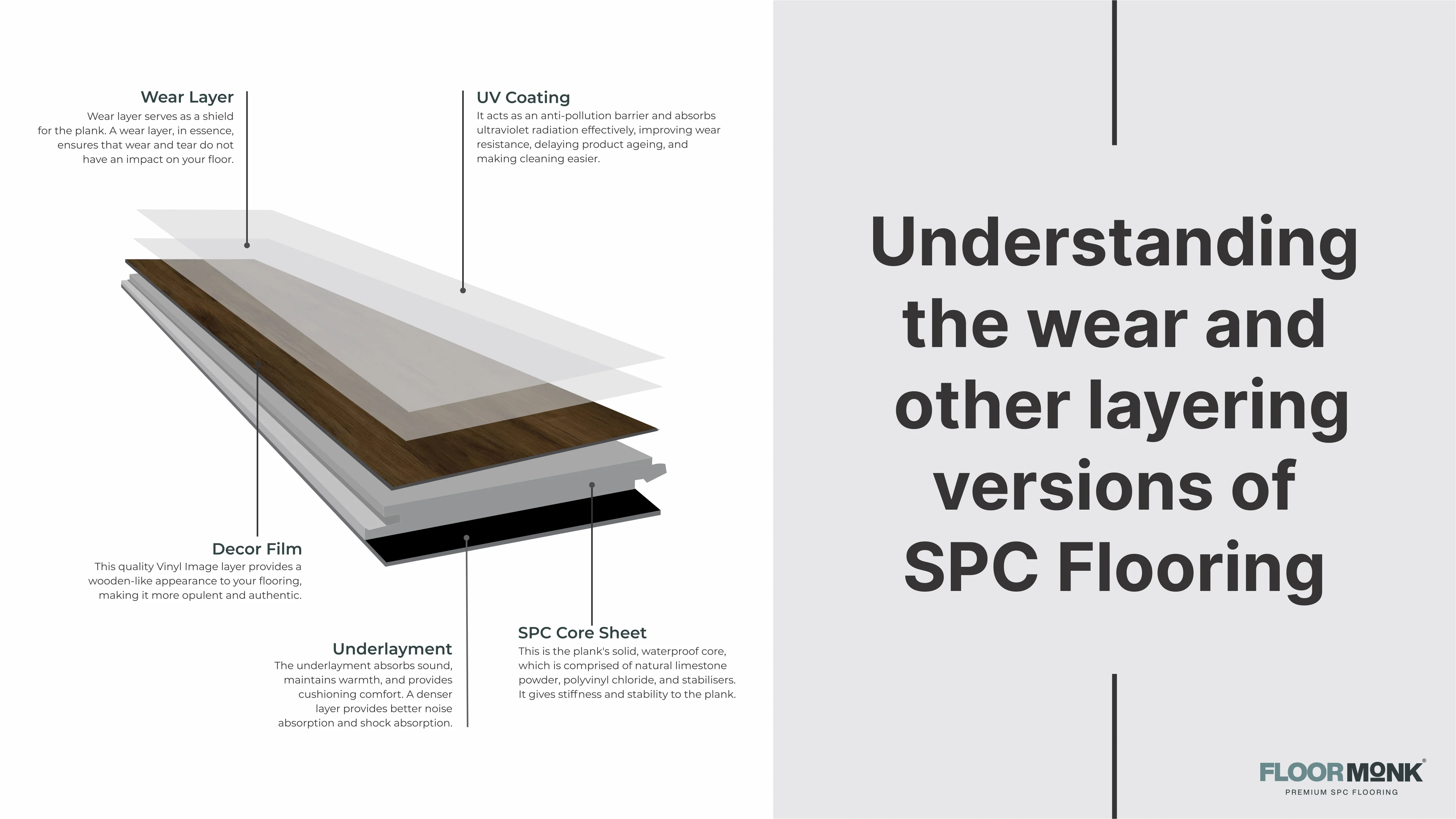

Wear Layer Thickness: Conforms to EN 429 (Pass) and ASTM F410 (Pass).

-

Dimension Squareness and Straightness: EN 427 (Pass - Squareness: 0.18mm, Straightness: 0.07mm).

-

Chemical Resistance: EN 423 (Pass), ASTM F925 and ASTM F1344 (Pass).

-

Colour Fastness to Artificial Light: EN20105.B02 Method A (Pass, Grade 6), ASTM F1515 (Pass).

-

Heat Stability by Color Change: Meets ASTM F1514 (Pass).

-

Castor Chair Suitability: EN 425 (Pass).

-

Residual Indentation: EN 433 (Pass, 0.06mm), ASTM F1914 and ASTM F970 (Pass).

-

Abrasion Group: EN 660-1/2 (Group T), ASTM F510, ASTM D3384 (Pass).

-

Impact Resistance: EN 433 (Pass), ASTM F1265, ASTM D2632 (Pass).

-

Dimensional Stability: EN 434 (Pass), ASTM F2199 (Pass, 0.1%).

-

Sound Reduction: EN ISO 717-2 (ΔLw: 2dB).

-

Flexibility: EN 435 Method A (Pass), ASTM F137 (Pass).

-

Slip Resistance: EN 13893 (Class DS), ASTM D2047-93 (Pass).

-

Electrical Resistance: EN 1081 Method C (Pass), ASTM F150-06 (Pass).

-

Thermal Resistance: EN 12664 (Pass).

-

Toxic Element Test: EN 71-3 (Pass, non-toxic, does not contain heavy metal or formaldehyde).

-

Behavior to Fire: EN ISO 11925-2, EN ISO 13501-1, EN ISO 9239-1 (Bf1-S1), ASTM E648-06 (Pass, Class 1).

-

Smoke Density: ASTM E662 (Pass, <450).

Fire Resistance and Safety

Proper fire safety is an important feature in any product, from building bricks to flooring, as it is a non-negotiable necessity. Therefore, SPC flooring is designed to reach extremely high marks of fire safety results and douse the fire instead of spreading it. Among the most common tests carried out to be able to prove that flooring is going to be safe from the aspect of fire safety, a test to EN 13501-1 and ASTM E648-06 standards is used, classifying materials according to their reaction to fire. This standard mainly scores the SPC flooring with high marks, being highly combustible and resistant to flames. By all this, SPC flooring extends its upper hand over others in commercial buildings when strictly considering the fire safety standards imposed.

Slip Resistance and Coefficient of Friction

Another safety feature is slip resistance, particularly for applications involving moisture, such as bathrooms, kitchens, and entryways. Slip resistance of a floor is measured by its coefficient of friction (COF), a factor that determines how easily a surface promotes slipping. Several standards are applied for the testing of SPC under conditions of different slip resistances, among them are EN 13893 and ASTMD2047-93. It checks the flooring under various conditions so that it will be safe even when moist. However, SPC flooring does prevent accidents and ultimately ensures that the surroundings of its user become safe as it meets or exceeds the standards.

Chemical resistance

SPC flooring is known for superior chemical resistance that can guarantee its durability and fine appearance when employed in chemically exposed environments. It meets the international requirements concerning chemical resistance. Flooring products pass tough testing processes that the SPC floor passes through: EN 423, ASTM F925, and ASTM F1344. These certifications ensure that SPC flooring is resistant to common household and industrial chemicals, thus not staining or discoloring or even degrading by such chemicals.

Wear Resistance and Durability

One of the leading factors that make flooring materials safe and long-lasting is their durability. Apart from the fine wear resistance, SPC flooring offers various advantages over its direct competition, but its resistance is critical in traffic-intensive areas. The flooring material is tested extensively to prove the product can indeed endure rigorous use without serious wear. Standards such as EN 13329 and ASTM F1700 also establish performance standards for flooring material wear resistance. SPC flooring ensures safe, functioning, and good-looking long-term performance, meeting or exceeding all these specifications even in the most demanding environments.

Impact Resistance

Impact resistance is one of the important safety requirements of flooring, especially in areas where it might be susceptible to the free fall of objects. Impact resistance tests of SPC flooring ensure that it will be able to absorb and withstand sharp hits without cracking or denting. Conformity to standards such as ASTM F1265, ASTM D2632 ensures that the SPC flooring can stand the wear and tear found in both residential and commercial spaces on a daily basis. This resistance not only extends the life of flooring but also contributes to overall safety by reducing the risk of injury from damaged surfaces.

Waterproofing and Moisture Resistance

One of the most notable features of SPC flooring is that it is waterproof, and therefore an excellent option for areas where much moisture flows, such as bathrooms, kitchens, and basements. It is not just convenient but also very vital to security as it inhibits the growth of mold as brought about by water damage and more health risks. The floor is subjected to various tests just to determine if the capability of being waterproof is up to world standards. Since this is highly resistant to water and moisture, SPC flooring contributes to a healthier and safer indoor environment.

Sound Insulation and Acoustic Performance

Comfort and safety are, therefore important in both residential and commercial settings. Underlayment is also found incorporated with the SPC flooring to improve its acoustic properties because it minimizes the noise between the floors. Such sound insulation is most valued in multi-story building structures where noise is something that is great to be avoided. Compliance with ENIS0717 - 2 means that the SPC flooring has been tested and meets Sound insulation levels as required.

Environmental and Sustainability Standards

As environmental concern keeps ascending, consumers and businesses seek safe and green flooring options. SPC flooring meets a range of stringent environmental standards and is, as such, an eco-friendly option. The manufacturing is certified under LEED-FS (Leadership in Energy and Environmental Design) and FSC (Forest Stewardship Council). It also ensures that the flooring materials are sourced in a way that is as sustainable as possible, as part of the general reduction of the environmental impact.

Installation Safety

Safe installation practices are one of the things that play a role in ensuring that flooring does what it is supposed to do and meet all the safety standards. SPC flooring is easy and safe to install. Most times, floors are featured with click-lock systems that minimize the application of adhesives, which can contain harmful chemicals. Also, SPC manufacturers guide with all certifications related to an installation safety standard, hence ensuring that the installation is carried out without compromising the safety of the flooring or the environment. Proper installation also ensures long- and successful-term flooring, so in the long term, it is a much safer option.

Why Standards Matter

These standards give SPC flooring certain performance criteria in the form of wear and tear resistance, chemical resistance, dimensional stability, and even slip resistance. Being the largest manufacturer and exporter of SPC flooring, Floormonk follows strict, international standards to ensure that all its products come in accordance with both European (EN) and American benchmarks.

The confidence developed by customers in floors that will last longer, remain looking great, and work perfectly even when put under heavy use is brought about by the assurance of choosing SPC flooring that does satisfy such standards.

Conclusion

SPC flooring is the best for both residential and commercial floors, providing durability, safety, and environmental responsibility. Being adherent to a wide range of global safety standards ensures that SPC flooring meets the ultimate benchmark in terms of fire resistance, slip resistance, chemical emissions, and so much more.

Whether you need flooring that is safe for your house, in the sense of your family and its comfort, or robust enough for commercial use, SPC flooring comes with comprehensive compliance with international safety regulations. Choosing SPC flooring, therefore means choosing a product that's not only befitting in terms of aesthetic value and functionality but also safe for you, your family, and the environment in the long run.